This mobile work bench is built for power tool usage. Compared to a traditional hand-tool bench, the top of a power tool bench is a few inches higher for two reasons: (1) power tools don’t require as much downward pressure as hand-tools, and (2) the additional height relieves pressure from the lower back when working (e.g., sanding).

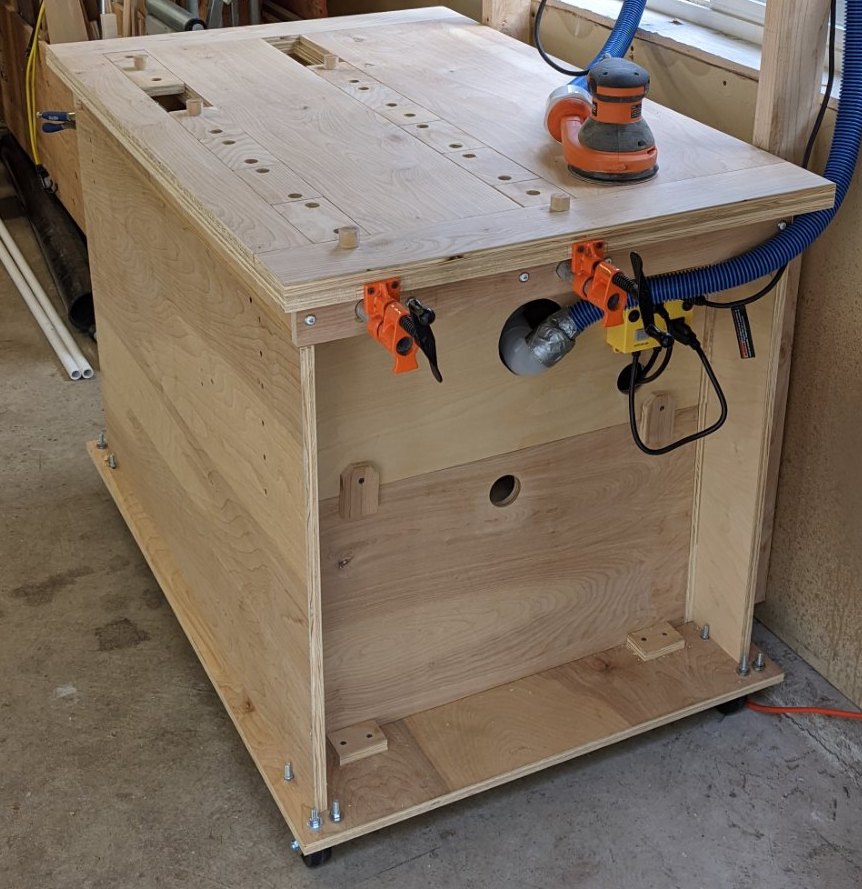

The bench is constructed with Birch plywood and mounted on heavy-duty casters (with brakes).

For flexibility and ease of use, the bench top contains two pipe-clamps along two tracks. By adding sliding bench dogs, it is simple to grip and clamp pieces of all shapes and sizes. The bench dogs are sleeved in vinyl tubing to avoid marring work.

Connecting a tool to the hose and plugging the tool into the outlet is all that is needed to get automatic dust collection. The bench contains a shop vac, cyclone, and dust collection bin. The vacuum draws through hose into the cyclone. The cyclone separates dust particles from large material. The dust is collected in a bin (easily emptied), and the large material continues to the shop vac.

The main feature of this bench is the automated power on/off functionality. By using an iVac switch, any time the power tool (plugged into the switch) is turned on, the shop vacuum is powered on. When the power tool powers down, the vacuum runs for a few more seconds (to clean up everything) and then turns off. No more reaching down to turn on/off shop vac before/after every on/off of the power tool.

Finally, cord and hose management is handled with o-rings, clips, and zip ties attached to the overhead cross-bar. The cross-bar functions well for hand plane storage, as well.